Geological Survey of Finland Goes Forward with the Digitalisation and the Automation of the GTK Mintec Mineral Prosessing Pilot Plant

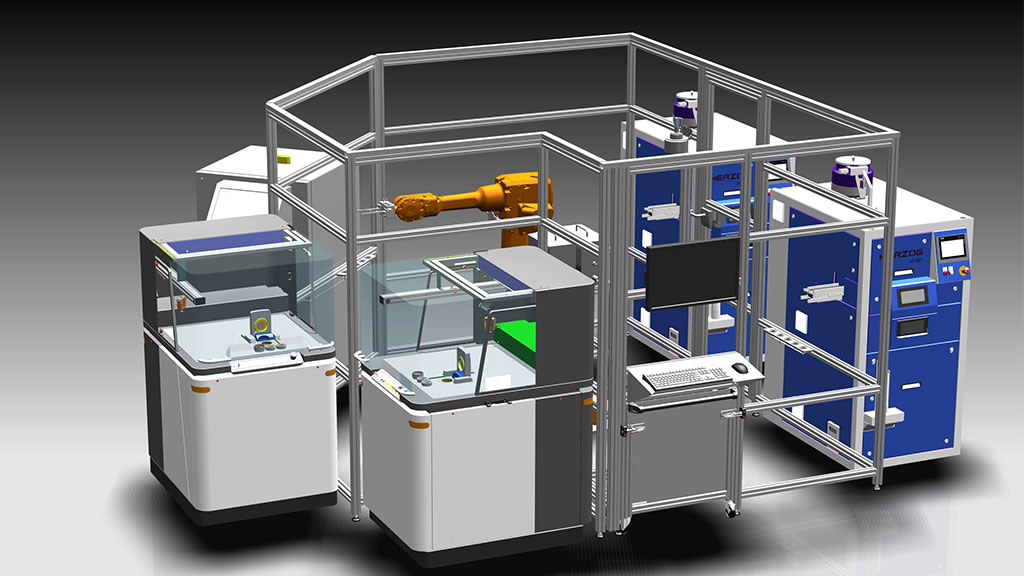

Geological Survey of Finland (GTK) is developing strongly material efficiency and circular economy research. As one part of this larger plan, GTK has acquired an automation system to GTK Mintec’s research platform in the town of Outokumpu, Finland. The system named as MintecRobo is acquired from Malvern Panalytical. More repeatable and faster chemical and mineralogical analysis makes the extraction process more efficient.

One part of the digitalisation at GTK Mintec is to increase the automation of processes and functions. Automation system from Malvern Panalytical to GTK Mintec Pilot Plant enables faster and more repeatable chemical and mineralogical analysis as well as increases the work safety and ergonomics.

“By having an automation at GTK Mintec Mineral Processing Pilot Plant we can tackle many issues in the mining and circular economy research. Ore grades are getting lower, circular economy materials and old tailings contain only small quantities of valuable minerals. Automation enables us to extract them more effectively and that way be more sustainable,” says Jouko Nieminen, Head of Unit at GTK.

GTK Mintec has more than thirty years of experience in enrichment research of minerals, metals, and industrial side streams in Finnish and international research and development projects.

“The need for many metals increases greatly as the energy transition progresses. It is even more important to have everything useful more accurately recovered during processing of materials. The digitalisation cooperation between GTK and Malvern Panalytical supports this great goal,” says Kimmo Tiilikainen, Director General at GTK.

MintecRobo will ensure direct feedback of changing conditions during ore processing whether due to changing ore compositions or varied process conditions. With that mining companies can save energy, increase recovery rates and the profitability of the whole mining operation.

“Automation and real-time monitoring of ores are mandatory for the transition towards net-zero carbon mining. The MintecRobo automation in combination with GTK Mintec’s mineral processing pilot plant will give mining companies a unique opportunity to test new procedures and processes to make mining operations not only more efficient and competitive but also ensure that mines fulfill its ESG commitments. Malvern Panalytical is proud to be part of the journey towards sustainable and net-zero mining.” says Dr. Uwe König, Business Development, Mining and Metals, Malvern Panalytical.

The MintecRobo will be assembled to the new facilities in the beginning of 2024. GTK Mintec has launched an extensive development project to enhance the green transition and digitalization.

More Information

GTK Mintec modernisation and digitalisation

Malvern Panalytical, Mining and Metals

Jouko Nieminen, Head of Unit, Geological Survey of Finland

+358 29 503 2180, jouko.nieminen@gtk.fi