From Mine Tailings to Tabletop – The Development of a Low-Carbon, Concrete-Like Product Advances

Material flows in the mining industry are abundant and full of opportunities. In the “SETELIT – Secondary Waste Streams, Added Value and Productization” project, explored how tailings could be used for example as material for a tabletop. The project also included 3D printing experiments using materials containing tailings. These practical experiments are driven by the desire to develop new applications for tailings and thereby reduce waste volumes.

The project involved practical research to promote the utilisation of tailings as a low-carbon, hardening material to replace concrete. Low-carbon goals were pursued by substituting traditional filler sand with tailings and by partially or fully replacing cement with secondary binders. In addition to reducing emissions, new applications for tailings also help decrease waste.

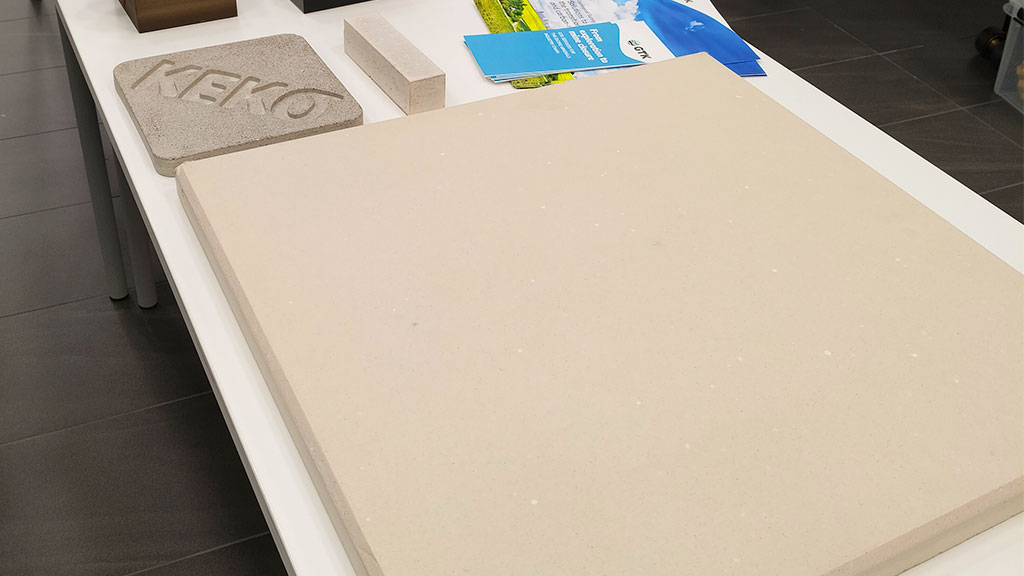

As part of the research, Keko Geopolymeerit Oy tested the production of a tabletop using geopolymerisation with tailings. Furthermore, the project experimented with 3D printing using varying amounts and qualities of tailings.

Beyond these trials, the SETELIT project advanced the development of a low-carbon, concrete-like product by building research infrastructure and services around the products. The project also developed a digital recipe tool for tailings-based, low-carbon hardened products and mine backfill.

Properties Assessed in Several Stages

Before the potential uses of tailings or other materials can be explored and tested, their properties must first be understood (characterised). This includes determining the material’s chemical composition, particle size, and any harmful substances it may contain.

When tailings or other materials are mixed with additional components, the resulting blend has its own chemical characteristics. It is essential to study how these substances interact to ensure sufficient strength and durability, as well as to check for the formation of harmful phases.

Research also employed X-ray tomography imaging to examine the structure without breaking the specimen. This method reveals features such as air bubbles, porosity levels, and their distribution within the structure.

In the project tests, a compressive strength of approximately 7 MPa was achieved with a specimen aged 28 days. During the hardening process, cement was partially replaced with slag, reducing the use of traditional binder. The material has potential applications, for example, as backfill material or in landscaping structures. Further research aims to improve compressive strength by reducing water content and increasing the proportion of coarse material, which may also lower the solubility of harmful substances.

Results from the SETELIT project and its predecessor, “Competence Development for Mine Backfilling Technologies” project, have been incorporated into a developing recipe library and tool, enabling better data management and utilisation. In SETELIT, multidimensional data was analysed using self-organising maps (SOM) to identify cause-and-effect relationships in material structure and behaviour, and to assess the material’s potential for further processing.

The project was implemented by Geological Survey of Finland GTK and Savonia University of Applied Sciences. Company partners were Agnico Eagle Finland Oy, Yara Suomi Oy, LKAB Minerals Oy, Alva Oy, Sika Finland Oy, Fatec Oy, Fescon Oy and Sibelco Nordic Oy. The project was financed by the implementers, company partners and the EU regional development fund ERDF (the regional council of Pohjois-Savo).

More information

SETELIT – Secondary Waste Streams, Added Value and Productization project webpage

Neea Heino, Research Scientist, Project manager

Geological Survey of Finland GTK

Tel. +358 29 503 5170

neea.heino@gtk.fi