Wear Caused by Ferrochrome Slag, or OKTO Aggregate, Behind Breakages of Vehicle Timing Belts

New research results reveal why vehicle timing belts break more often in the Oulu region than in other parts of Finland. Various research organisations participated in the study to investigate potential reasons behind the breakages. Eventually, ferrochrome slag, a material used broadly as aggregate in asphalt in the Oulu region, was discovered as the cause of the problem.

Breakages of vehicle timing belts in the Oulu region were investigated in an extensive multidisciplinary study started in 2019. It revealed that ferrochrome slag, or OKTO aggregate, released from asphalt and carried to timing belts together with road dust was behind the problem. According to previous studies and car dealerships’ warranty repair statistics, vehicle timing belts wear and break many times more frequently in the Oulu region than in other parts of Finland relative to the number of vehicles.

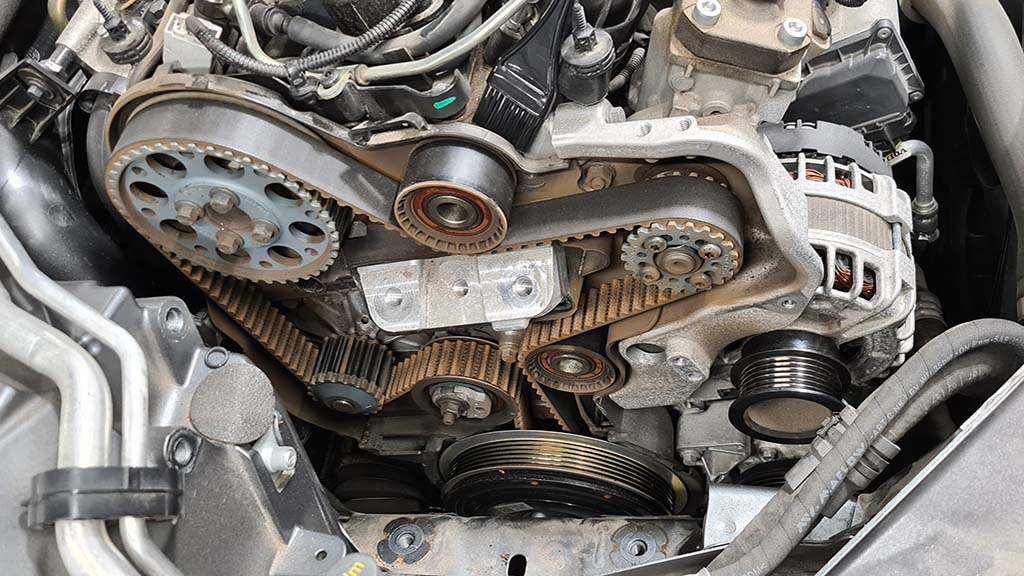

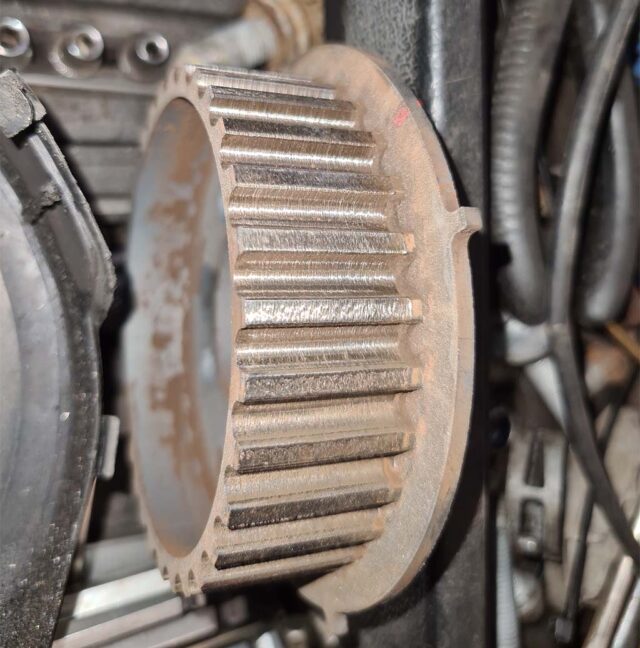

The study systematically investigated differences in road dust and environmental factors between the Oulu region and the Helsinki metropolitan area, among others, and analysed any factors that affect wear. The problem was found to be caused by abrasive wear, not by corrosion or chemical reactions. This refutes many of the previously proposed possible explanations, as they would have required corrosion or chemical reactions. As the study progressed, it was discovered that ferrochrome slag, or OKTO aggregate, used in asphalt was the cause of abrasive wear. When the asphalt aggregate wears due to use of studded tires, sharp-edged and hard road dust is formed from it, which then grinds and wears timing belt gears.

“Various causes of timing belt breakages have been proposed over time. As a result, we decided to investigate them and exclude any irrelevant factors,” says Perttu Niskanen, Project Manager and University Teacher at the University of Oulu.

Mika Räisänen, Senior Scientist at the Geological Survey of Finland (GKT), says: “We obtained useful initial information from our asphalt and road dust studies, as well as previous studies related to the timing belt problem. Road authorities provided us with valuable information about the materials used. The dialogue between us and companies played a crucial role considering practical arrangements. All of this helped us focus our studies on local road dust in the Oulu region, which is a cause of abrasive wear and whose composition differs significantly from road dust in other parts of Finland.”

Ferrochrome slag generated as the steel industry’s by-product has been broadly used in road sections with high traffic volumes in the Oulu region to replace natural aggregates.

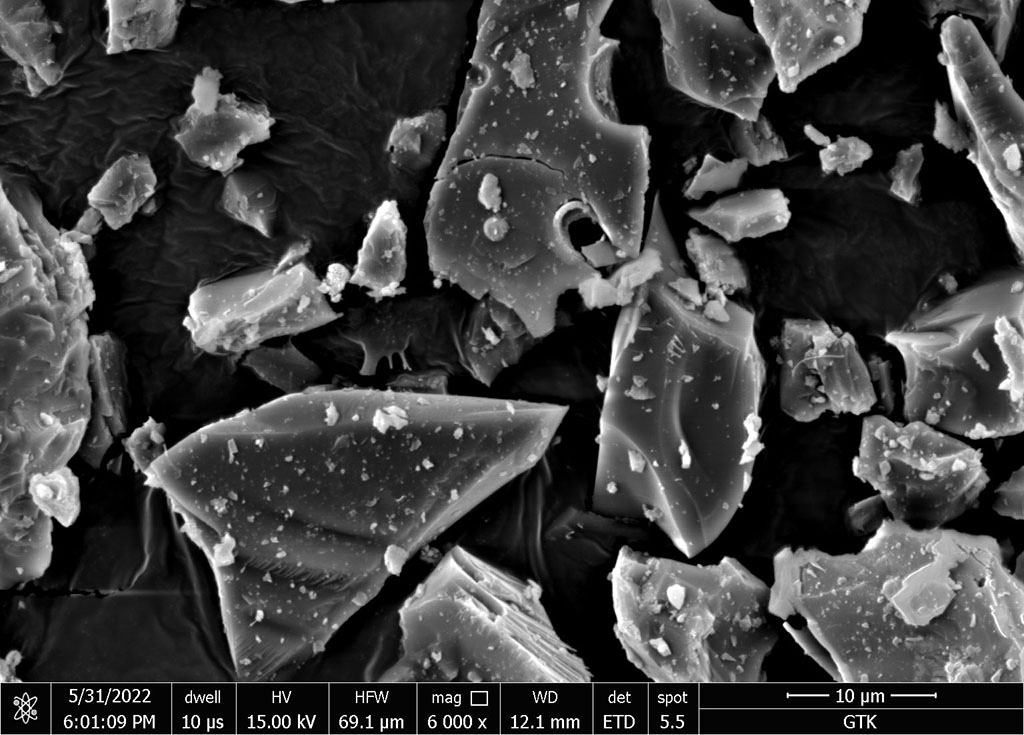

A Comprehensive Study with Convincing Results

The project involved extensive multidisciplinary cooperation. Investigating the problem has required high expertise in vehicle technology and applied mineralogy, as well as extensive sampling, with numerous samples being taken from asphalt, road dust on the road surface and in the air, vehicle engine compartments and inside the timing belt housing. More than 3,000,000 individual analyses were analysed using an electron microscope – roughly 100 times more than in all of the previous studies combined (tens of thousands). The samples were used to identify the composition of the asphalt aggregate and road dust.

More than 3,000,000 individual analyses were analysed using an electron microscope – roughly 100 times more than in all of the previous studies combined.

During the project, test equipment to model the timing gears of combustion engines were designed and built. The equipment clocked more than 3,000 hours of tests. The tested dust was made to correspond to the dust collected from vehicle engine surfaces in the Oulu region with regard to its grain size distribution and dust particle shapes.

“In our tests, the wearing effect of ferrochrome slag was as much as 25 times higher compared with other tested rock aggregates used in roads. This is a massive difference,” says Jonne Untinen, Project Researcher at the University of Oulu, summarising the results.

“Based on the significant testing programme, we can prove that ferrochrome slag is the key factor behind timing belt breakages. Our studies and diverse tests offer valuable information for road authorities to support their future planning processes,” Niskanen and Räisänen say.

AutoOsaLiike is a joint project between research organisations and businesses in the Oulu region to develop the vehicle industry and solve the timing belt problem in the region. The project is coordinated by the University of Oulu’s Materials and Mechanical Engineering research unit. The project’s partners are Geological Survey of Finland, the Finnish Environment Institute, Lapland University of Applied Sciences, Metropolia University of Applied Sciences, and a number of vehicle industry companies. AutoOsaLiike started in 2019 and will continue until the end of 2022. The project has received European Regional Development Fund (ERDF) funding from the Council of Oulu Region.

Multidisciplinary and high-quality research, combined with cooperation between research and business, produces significant shared intellectual capital. The AutoOsaLiike project shows how important it is to develop new multidisciplinary research methods when assessing the long-term sustainability and quality of mineralogical raw materials of the circular economy in their final applications.

Additional information

Mika Räisänen, Senior Scientist

Geological Survey of Finland GTK, Energy and Construction Solutions

tel. +358 29 503 2223, mika.raisanen@gtk.fi

Perttu Niskanen, University Teacher, Project Manager of the AutoOsaLiike project

University of Oulu, Materials and Mechanical Engineering research unit

tel. +358 50 350 6013, perttu.niskanen@oulu.fi

Related topics

- Find out how GTK studies the Circular Economy and the utilisation of industrial side streams in construction:

New Methods to Promote Circular Economy in Earthworks - More information on GTK’s Sustainable Construction services

- More information on GTK’s Circular Economy services

Geological Survey of Finland: Solutions to accelerate the transition to a sustainable, carbon-neutral world

The Geological Survey of Finland (GTK) produces impartial and objective research data and services in support of decision-making in industry, academia, and wider society to accelerate the transition to a sustainable, carbon-neutral world. GTK employs more than 400 experts specializing in the mineral economy, circular economy, solutions related to energy, water and the environment, as well as digital solutions. GTK is a research institution governed by the Finnish Ministry of Employment and the Economy, operating in Finland and globally.